Innofab’s high-speed, high-quality offsite manufacturing not only delivers serious cost efficiencies, it’s also more sustainable, producing 70% less waste.

Partner with us for speed, quality, safety, and sustainability.

What we do

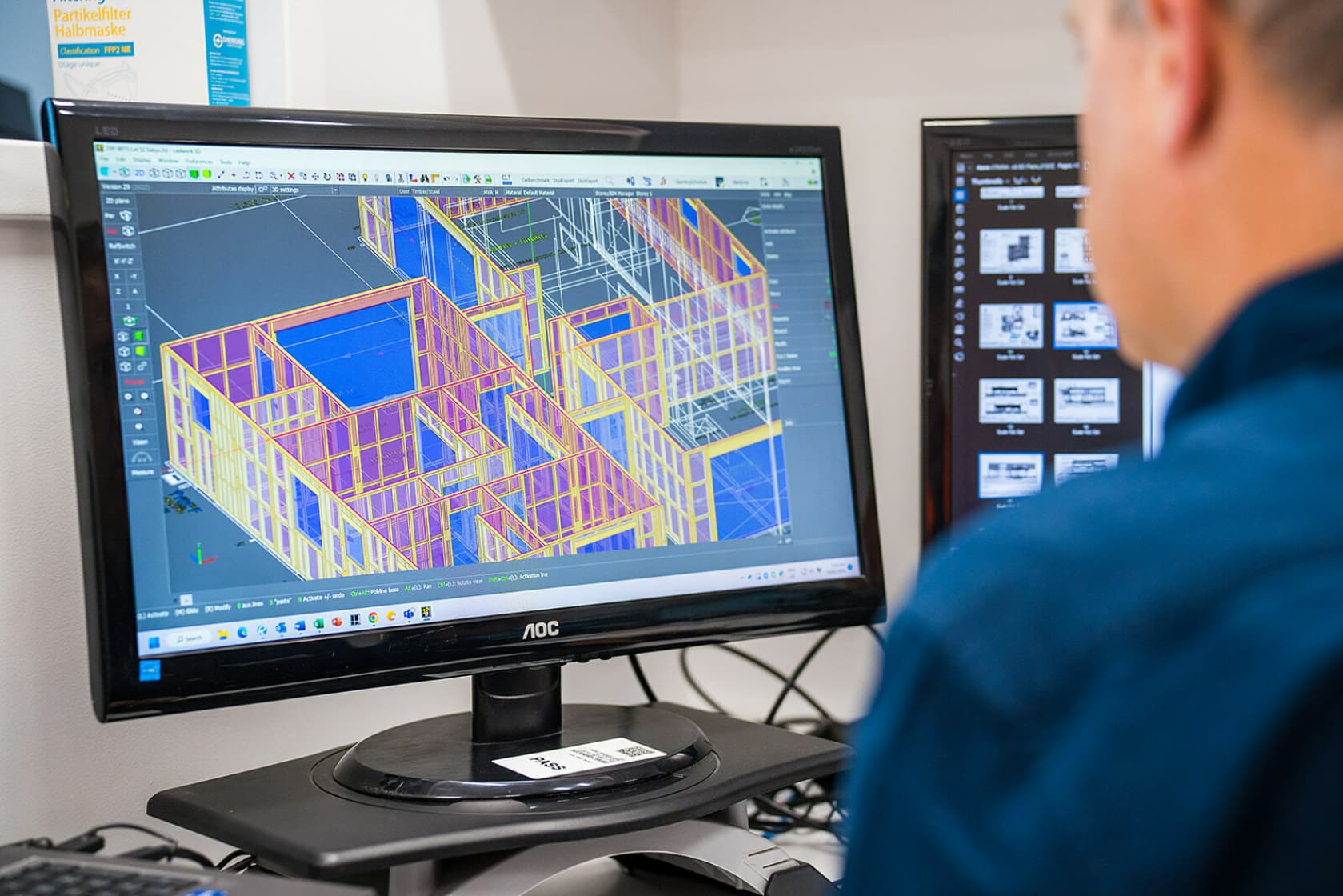

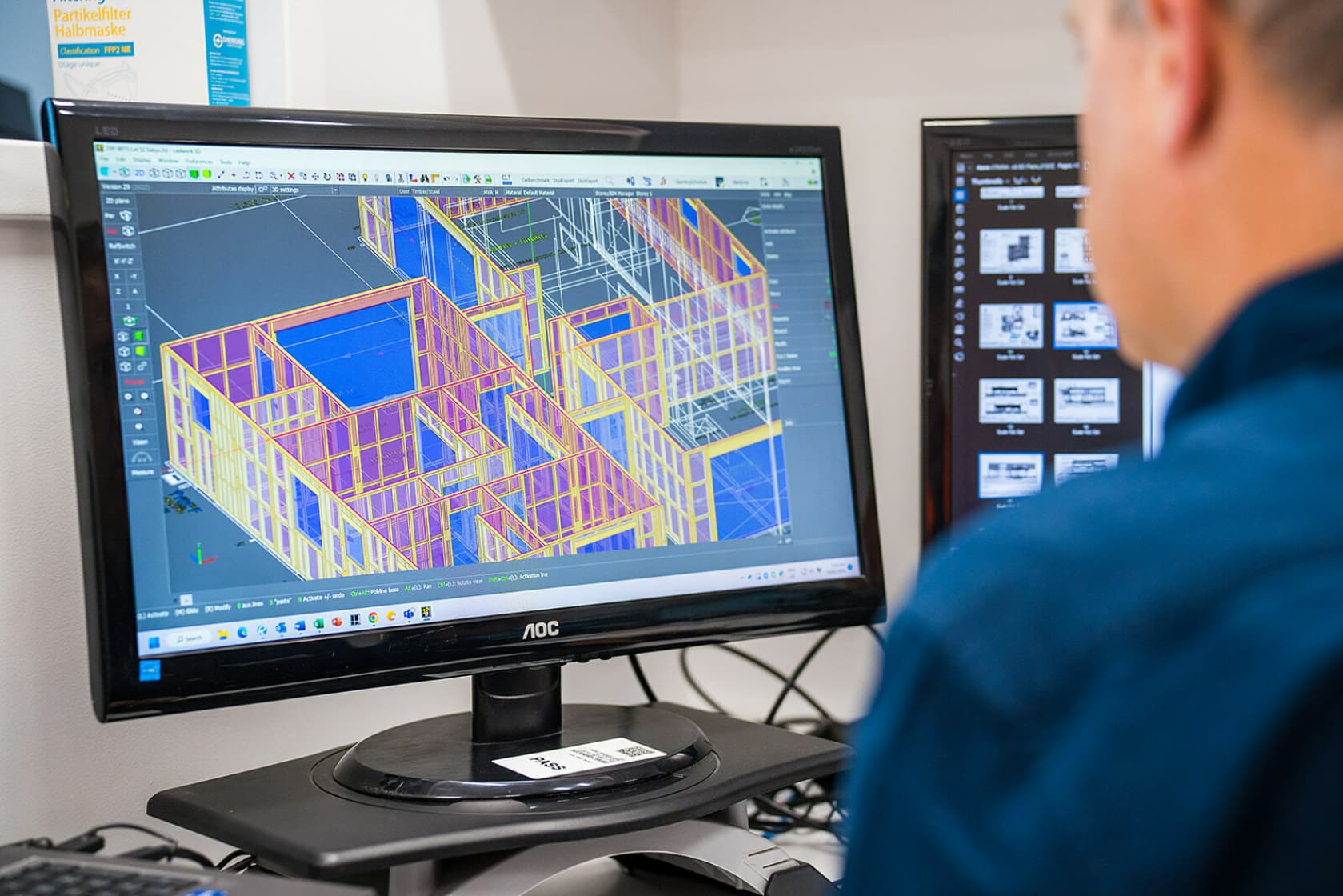

Innofab specialises in pre-fabricating the main components that make up buildings across Aotearoa New Zealand; from homes, to schools, to retirement complexes, apartments and offices. We combine innovative digital technology with a world-class factory in Christchurch to deliver high-speed, high-quality production into the construction supply chain.

Our solutions

Sector solutions

Innofab solutions have been used in builds across Aotearoa New Zealand, from social housing construction to schools and commercial buildings.

Building component solutions

We also offer a suite of prefabricated components and buildings, such as portable bathroom pods.

Sustainability

Did you know, up to 50% of New Zealand’s waste comes from construction and demolition? That’s why we’ve designed Innofab’s prefabricated buildings and components to generate 70% less waste than traditional building methods.

- We use technology during design and detailing to ensure accuracy, reducing waste by cutting panels to the exact length.

- While we work off-site, projects can continue simultaneously, reducing on-site activities such as noise, ground disturbance and vehicle movements.

- Waste and disruption are further reduced when components and building arrive on site near completion.

- We also use LVL timber to create a stronger structure that lasts longer as well as being recyclable and renewable.

Build smarter with Innofab.

Get in touch to find out how we can bring speed, quality, safety, and sustainability to your next project.